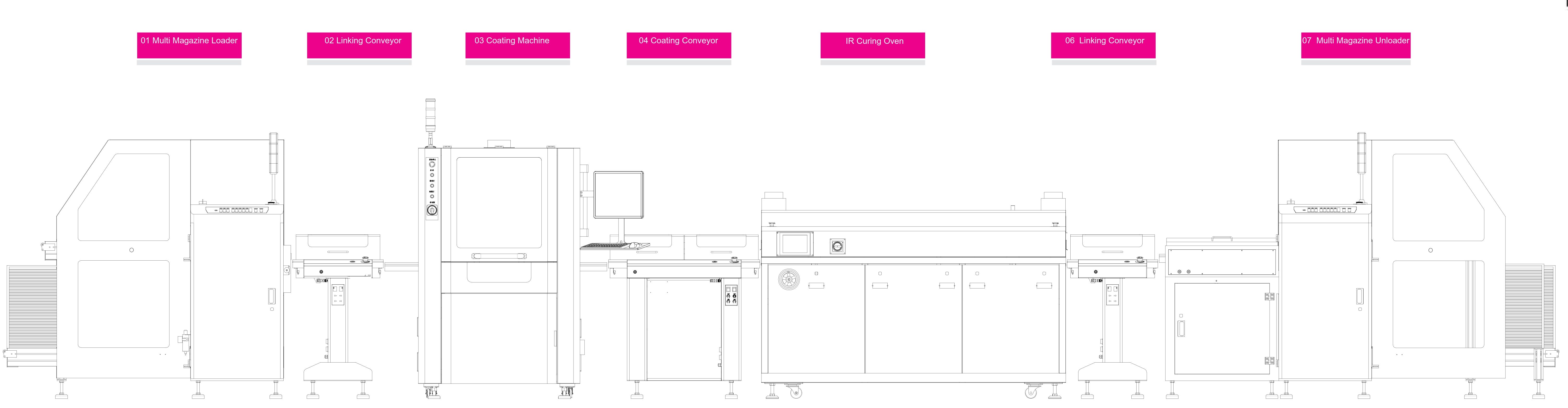

Coating & Curing Systems

Inline curing ovens - Curing systems

UV and IR Curing Ovens and Systems

Welcome to our category for UV drying and IR drying in electronics manufacturing!

Here you will find a comprehensive selection of high-quality UV drying and IR drying ovens,

which have been specially developed for the requirements of the electronics industry.

Our UV drying ovens are the ideal solution for efficiently and precisely drying electronic components and PCBs. UV drying is a proven method to accelerate the curing process of UV-curing materials, such as paints, adhesives, and inks. With our UV drying ovens, you achieve uniform drying, minimize downtime, and increase production capacity.

Why UV Drying is Needed in Electronics Manufacturing:

- Rapid Curing of UV-Curing Materials: UV drying ovens significantly accelerate the curing process of UV-curing coatings, adhesives, and inks.

- Efficient Curing of PCBs: In electronics manufacturing, UV-curing materials are often used on PCBs. A UV drying oven ensures that these materials cure quickly and uniformly, increasing production speed.

- Minimization of Adhesion Issues: Fast curing of adhesives and coatings reduces adhesion problems between different layers, resulting in better product quality.

- Precise Control of Curing Time: UV drying ovens provide the ability to precisely control curing time, crucial for achieving the desired hardness and properties of materials.

- Energy Efficiency: Like IR drying ovens, UV drying ovens are energy-efficient and require less energy than other drying methods.

- Environmentally Friendly: UV drying generates no harmful emissions or waste materials, making it environmentally friendly and reducing the manufacturing's ecological footprint.

IR Drying in Electronics Manufacturing:

Our infrared drying ovens provide a reliable method for rapid drying of electronic components and assemblies. Infrared drying uses infrared radiation to remove moisture from materials and accelerate the drying process. This technology allows for precise temperature control and minimizes the risk of damaging sensitive electronic parts.

Why IR Drying is Needed in Electronics Manufacturing:

- Precise Temperature Control: IR drying ovens enable precise control of the drying temperature. This is crucial to ensure that sensitive electronic components and materials are not overheated or damaged.

- Rapid Drying: IR drying is particularly efficient at quickly removing moisture from materials. This is important to expedite the manufacturing process and avoid bottlenecks.

- Uniform Drying: Infrared drying provides even heat distribution across the entire drying surface, resulting in consistent drying results and preventing material deformations.

- Energy Efficiency: IR drying ovens are more energy-efficient than conventional drying methods. They require less energy to reach and maintain the desired drying temperature.

- Customizability: IR drying ovens are available in various sizes and configurations to meet the diverse requirements of electronics manufacturing. They can be adapted to specific production processes.

- Gentle Treatment of Sensitive Materials: Since IR drying is a contactless drying method, it does not physically affect or damage sensitive electronic components, ensuring product quality.

- Reduced Downtime: The rapid drying performance of IR drying ovens minimizes downtime in manufacturing, as materials can be processed quickly.