Concepts for all aspects of PCB protective coating

Conformal Coating process:

Conformal coating is a thin layer of material applied to the surface of an electronic circuit or device to protect it from harsh environments. It is used in the electronics manufacturing industry to protect electronic components from moisture, dust, chemicals, and other harmful substances.There are several different types of conformal coatings available, including acrylic, silicone, polyurethane and more. Each type has its own set of properties and is suitable for different types of electronic devices and applications.

Applying conformal coating is typically done by a Conformal Coating Machine by brushing, dipping, or spraying the coating onto the electronic device. A skilled technician applies the coating carefully ensuring that it covers all areas of the circuit board, without blocking any of the electrical contacts or creating any short circuits.

Conformal coating is a critical step in the electronic manufacturing process, as it helps to ensure the reliability and longevity of electronic devices. It is an effective way to protect electronic components and help them to perform as expected, even in harsh and demanding environments.

Conformal Coating Solutions

Planning and manufacturing expertise from A to Z

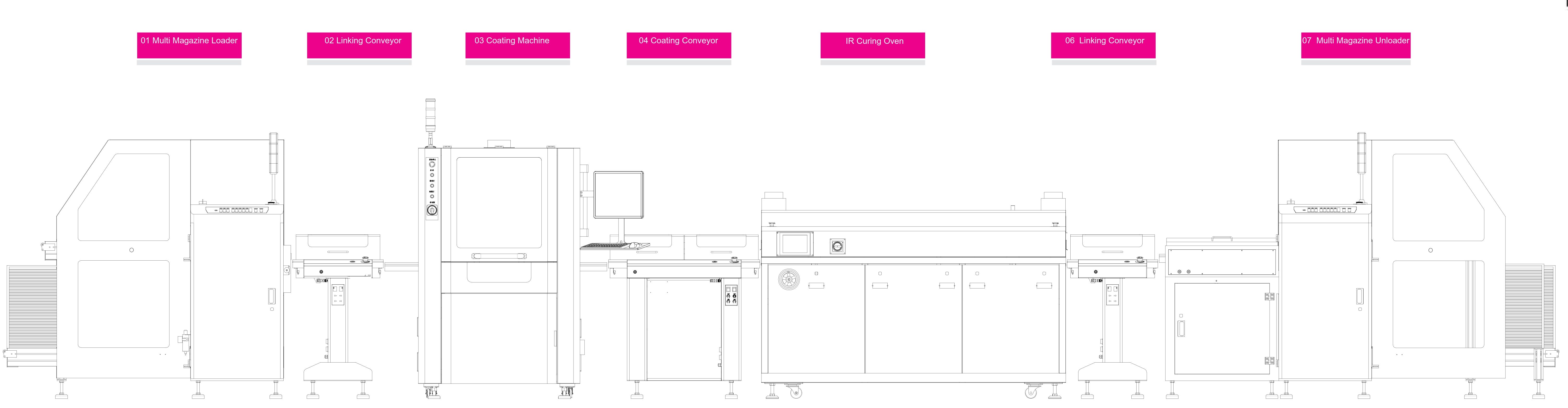

Full Process Schematic

Individuelle Planung & Beratung