Soldering Machines

Soldering Equipment for your electronic production

We offer you a wide range of products from our own production, from small compact offline systems to modular expandable dual-lane systems, for your thermal applications. We can offer you solutions for Reflow Soldering, Wave soldering, Selective soldering, Soldering robots with Iron-tips soldering technology as well as curing and drying technologies.

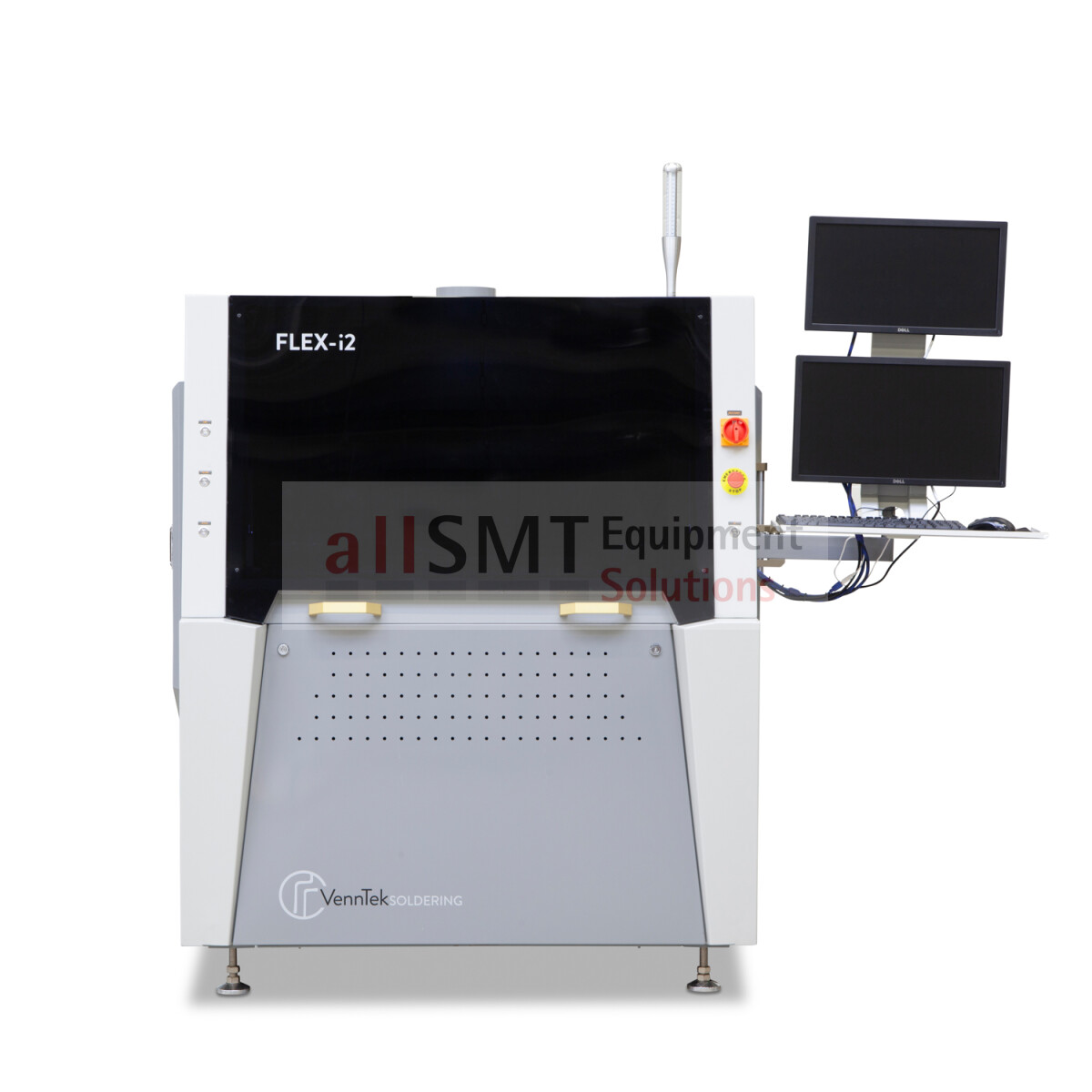

allSMT covers the entire soldering process chain with its own brand "VennTek".

Our development department is also happy to respond to customer requests. Please contact us!

-

Selective soldering

Selective soldering is extremely versatile and can be used in various applications. Selective soldering systems are suitable for soldering THT (AI) components, power components and more. The adaptability of this process makes it the ideal choice for modern and flexible electronics manufacturing.

-

Reflow Soldering

The most common soldering process in electronics manufacturing is Reflow soldering. A printed circuit board already equipped with solder paste and SMD components is supplied with thermal energy under a defined time profile. The assembly heats up until the melting point of the solder paste is reached and thus forms on the pad.

Our Reflow systems use convection-reflow-soldering principle. -

Wave Soldering

Wave soldering is ideally suited for soldering wired (THT,AI) components as well as thermally demanding printed circuit boards. The special feature of wave soldering is the transport of the assembled PCB underside via a solder wave. The soldering points are wetted with solder and thus form.

However, the soldering process is preceded by the application of flux and preheating of the assembly.

-

For drying and curing we can also offer you solutions from our company.

The curing and drying of protective coatings and encapsulants is a common process in the backend area of electronics manufacturing. IR drying systems are similar to Reflow systems, but these systems do not require different components, which allows a more compact design.

Contact Us for Consultation

If you have any questions or need personal guidance, we are here to assist you. Feel free to get in touch with us to learn more about our high-quality SMT Feeders and storage solutions. We look forward to helping you optimize and refine your manufacturing processes.