Automated storage systems

Optimize your Electronics Manufacturing with SMT Reel Storage Systems

In electronics manufacturing and SMT (Surface Mount Technology) production, efficiency and precision are very important. Automated storage systems have become a big help, changing how parts are stored, retrieved, and managed during production.

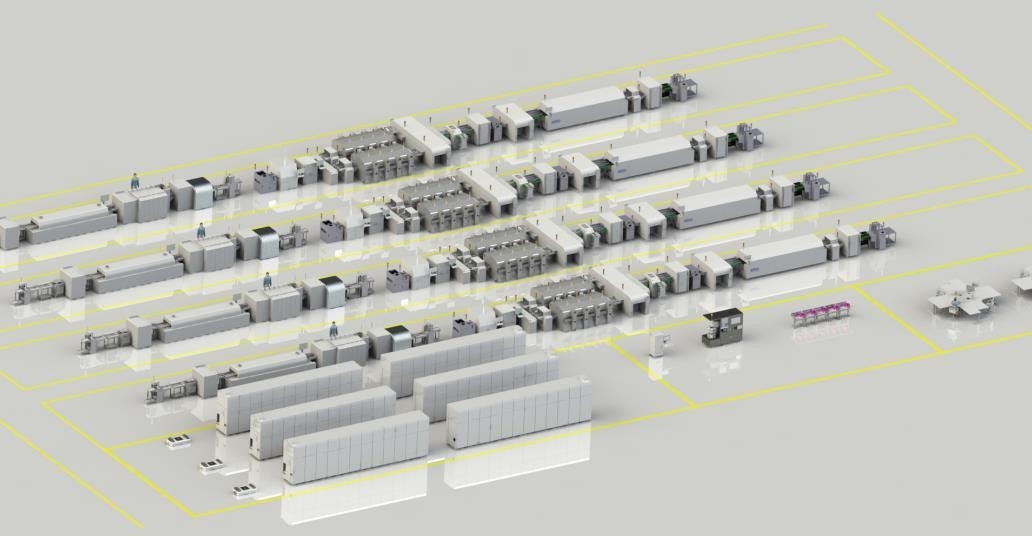

SMART SMT FACTORY SYSTEM LAYOUT

The Importance of Automated SMD Reel Storage in SMT Manufacturing

SMT manufacturing places have special challenges when it comes to storing and retrieving parts. With thousands of SMT Reels to manage, old storage methods often don't work well. Automated storage systems solve these problems, offering many benefits that are essential for modern electronics production.

One big advantage of automated storage systems is that they save space. In a typical SMT-Line, floor space is valuable. Vertical storage solutions, like Vertical Carousel Modules (VCMs) and Vertical Lift Modules (VLMs), can save up to 85% of floor space compared to regular shelving systems. This lets manufacturers use their space better without reducing storage capacity.

Also, automated storage systems make inventory management much better. Real-time tracking makes sure that stock levels are always accurate, reducing the risk of production delays due to running out of parts. This precise inventory control is crucial for keeping production running smoothly and meeting tight deadlines in the fast-paced electronics industry.

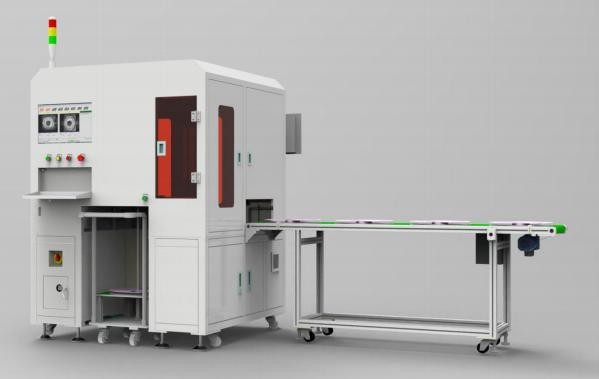

Key Features of Automated Storage Systems for SMT Production

High-Density Storage

Optimized storage for components and PCBs

Fast Retrieval

Quick access to materials keeps production moving

Seamless Integration

Works with other SMT equipment

Real-Time Tracking

Live inventory management and monitoring

ESD Protection

Safeguards sensitive components

Climate Control

Maintains optimal storage conditions

Real-time Inventory Tracking

Ensures accurate stock levels

MES Integration

Seamless connection with production systems

Integration of Automated Storage Systems with SMT Production Lines

One of the biggest advantages of automated storage systems is that they can easily connect with existing SMT-Lines. This connection creates a smooth flow of components from storage to production, reducing downtime and increasing efficiency.

Autonomous Transport Vehicles can be directly connected to automated storage units, ensuring a constant supply of parts to pick-and-place machines. Delivering components just when they're needed reduces work-in-progress inventory and improves overall production flow. Also, automated replenishment processes can trigger reorders based on set levels, making sure that stock levels are always optimized.

The integration goes beyond physical connections. Modern automated storage systems can communicate with Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP) software. This data exchange allows for real-time production planning, inventory forecasting, and performance analysis, giving a complete view of the entire manufacturing process.

- More Accurate: They're right 99.9% of the time when picking items, which means fewer mistakes.

- Faster: Parts can be found and retrieved quickly, so production doesn't slow down.

- Better Inventory Control: The system knows exactly what's in stock at all times.

- Safer: Workers don't have to lift and carry as much, which is safer for them.

- More Productive: Workers can focus on making things instead of looking for parts.

-

Better Tracking: The system keeps a record of everything, which helps with quality control.

By connecting these storage systems with software solutions, factories can work even more efficiently. Everything works together smoothly, from storing parts to making the final product.

Adding Automated Storage to Your SMT Factory

If you want to add an automated storage system to your SMT factory, here are some steps to think about:

- Figure out how much storage you need now and in the future

- Choose the right type of storage system for your factory

- Plan how it will work with your other machines and computers

- Train your workers on how to use and take care of the new system

- Keep an eye on how well it's working and make changes if needed

The goal is to make your factory work better and produce more. By planning carefully, you can make your SMT production much better with an automated storage system.