SMT line concepts - Manufacturing - Production - Assembly

What is an SMT Production Line?

Surface Mount Technology

A state-of-the-art electronics manufacturing line for the surface mounting of SMD components is a high-tech system for manufacturing electronic devices. It consists of several interconnected machines that work together (inline) to mount electronic components on printed circuit boards (PCBs) with high speed and precision.

The Complete SMD Manufacturing Process at a Glance

Discover the most advanced components of an SMT production line

PCB Loading

The first step in the SMD process is the automated loading of the PCBs. With high-precision loading systems, the boards are reliably and gently introduced into the production line.

Technology: Automated magazine loading with optical position control

Solder Paste Printing

The precise application of solder paste is crucial for the quality of later solder joints. Our stencil printer works with the highest precision and SPI inspection for optimal results.

Technology: Fully automated stencil printer with SPI control

SMD Assembly

Modern pick-and-place machines place SMD components with the highest speed and precision onto the PCB. Assembly machines reach placement rates of up to 120,000 components per hour.

Technology: High-speed placement machines with optical verification

Reflow Soldering

In the reflow oven, all SMD components are soldered simultaneously. Thanks to precise temperature profiles and controlled atmosphere, reliable solder joints of the highest quality are produced.

Technology: Convection reflow oven with optimized temperature profiles

Automatic Optical Inspection (AOI)

High-resolution cameras and AI-powered software inspect each assembly for placement and soldering errors. The AOI guarantees compliance with the highest quality standards.

Technology: AI-based 3D AOI with automatic error detection

PCB Unloading

The last step is the automated unloading of the completed assemblies. The assemblies are gently ejected from the production line and prepared for further processing.

Technology: Automated unloading stations with traceability function

SMD Component Storage

Intelligent storage systems ensure the safe and moisture-controlled storage of sensitive SMD components. Automated inventory management ensures optimal stock control.

Technology: Climate-controlled storage systems with MSD protection and traceability

Autonomous Transport Vehicles

Advanced AGVs like the QF-300C transport materials and assemblies reliably and autonomously between production stations. Intelligent navigation optimizes transport routes.

Technology: QF-300C AGV with laser navigation and 300kg load capacity

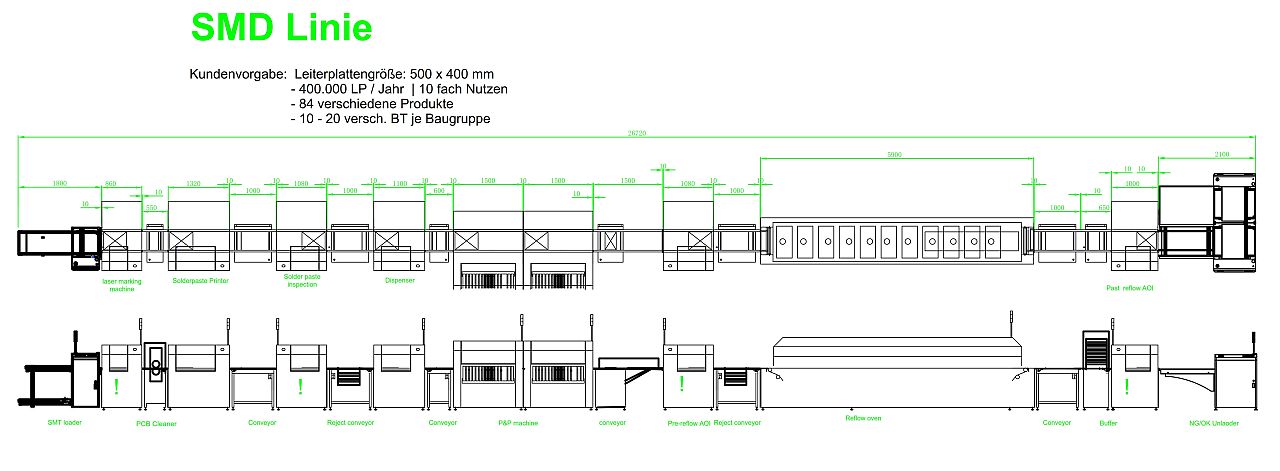

Visualization of an SMD Line by allSMT.

SMD production line using an LED manufacturing example.

SMT production concepts, from planning to populated PCB.

Our manufacturing expertise covers everything from A to Z, including all the steps necessary for efficient and precise production.

Frequently Asked Questions about SMD Manufacturing

What is an SMT Production Line (Surface Mount Technology)?

A state-of-the-art electronics manufacturing line for the surface mounting of SMD components is a high-tech system used to manufacture electronic devices. It typically consists of several interconnected machines that work together (inline) to mount electronic components onto printed circuit boards (PCBs) with high speed and precision.

A typical SMT manufacturing process includes:

-

SMD Stencil Printer: This machine applies solder paste to the PCB using a screen printing process. This is usually done automatically at high speed and precision. [Details about stencil printers]

-

SMT Placement Machine: This machine uses advanced robotics to place individual SMD components onto the PCB. It typically has a high-resolution vision system that can precisely identify and locate the components on the board. [Details about placement machines]

-

Reflow Soldering Oven: This machine uses heat to melt and reflow the solder paste that attaches the components to the PCB to form an electrical connection. The oven is usually equipped with advanced temperature control systems to ensure the solder reaches the correct temperature for the appropriate amount of time. [Details about reflow soldering]

-

Automatic Optical Inspection Machine (AOI): This machine uses advanced cameras and software to inspect the PCB for defects or errors in component placement. [Details about AOI systems]

-

Cleaning System: This machine removes excess flux and residue from the PCB to ensure it is clean and ready for final assembly.

-

PCB Transport Systems: When SMT production lines are operated inline (linked), this involves special modules such as PCB handling systems: These devices ensure secure transport of PCBs between the various machines. The boards are automatically placed on a conveyor by a depiler and moved to the next module. At the end of production, the PCBs are stacked into a magazine for further processing. [Details about PCB handling]

-

MES Software - Traceability: Modern SMT manufacturing operations (EMS providers) use software to control and monitor the SMT production line. This usually includes real-time monitoring and control of machines as well as advanced data analysis tools that help optimize the production process and contribute to traceability.

-

Innovative AI Production Optimization: The latest innovation in the manufacturing industry is our AI-based production optimization software. This patented platform revolutionizes how production data is captured and analyzed by monitoring activities from both machines and operators in real time. By integrating AI and sensor fusion, this software provides deeper insights into production workflows and offers unprecedented opportunities for optimization and efficiency improvements.

-

Autonomous Transport Vehicles (AGV): Modern manufacturing lines are increasingly using driverless transport systems for internal logistics. These autonomous vehicles transport materials and components between various stations and optimize material flow. [Details about transport vehicles]

-

Automated Storage Systems: Modern storage systems ensure efficient component supply by storing moisture-sensitive components under optimal conditions and automatically providing them as needed. [Details about storage systems]

Overall, a modern SMD line is an extremely complex and sophisticated system, requiring a high level of technical expertise to operate and maintain. It is designed to produce electronic components quickly, efficiently, and with high precision, reducing human error and maximizing production yield and productivity.

Planning a New SMT Production Line?

Would you like to take your SMT production line to the next level? Whether you are planning a complete setup, an expansion, or an optimization of your existing production, we offer tailor-made solutions that are perfectly suited to your needs.

As an international company, we have the expertise and experience to make your production line efficient and future-proof. We will guide you from the initial planning stage to full implementation, whether you are operating in Europe, Asia, or North America.

Our expertise covers all aspects of SMT technology, and we work closely with you to optimize your production processes and increase your competitiveness.

Schedule a Consultation

Reference of an SMT-Productionline

Planning and manufacturing expertise from A to Z

Why We Are the Right Partner for You

Global Network

We successfully collaborate with companies worldwide, providing solutions tailored to local markets and production requirements.

Customized Solutions

Each production line is individually designed to meet your specific requirements and ensure maximum efficiency.

Long-Term Partnerships

Our support doesn't end with the installation. We offer comprehensive service and support for the long term.

Immediately available Total Line Solutions - SMT lines - new and used