Is your production ready

for the future of

electronics manufacturing?

allSMT provides you with cross-technology machines and process solutions for professional PCB assembly.

International Standards, Locally Implemented

allSMT implements international automation standards, adapted to your local conditions and processes.

Don't reinvent, optimize!

"Leverage proven system configurations and processes from existing resources – we help you boost efficiency!"

Now is the right time!

"The future won't wait – the perfect time to automate your production is now!"

Optimal use of existing resources!

"Our strategies for reusing existing machines and systems save costs and increase efficiency."

Risk reduction through proven solutions!

"Minimize risk with technologies tested hundreds of times and efficient automation."

Efficiency through experience!

"Rely on our experience in implementing proven system configurations for maximum production capacity."

Your Full-Service Partner for Electronics Manufacturing

From consultation to global service - Everything from a single source

EXPERT CONSULTATION

Expert knowledge for your SMT manufacturing

DEVELOPMENT

Innovative solutions for your processes

PRODUCTION

In-house manufacturing

PROCESS SOLUTIONS

Optimized manufacturing processes

PURCHASE

Fair valuation of your equipment

SALES

Certified machines (SMT & THT)

TRAINING

Professional further education

GLOBAL SERVICE

Global support & maintenance

Our Portfolio

Achieve your GOALS – with Solutions from allSMT

Do you need something special?

Our complete portofolio includes far more than is presented here.

Let us work together to find the perfect solution for you - we're just a phone call or email away.

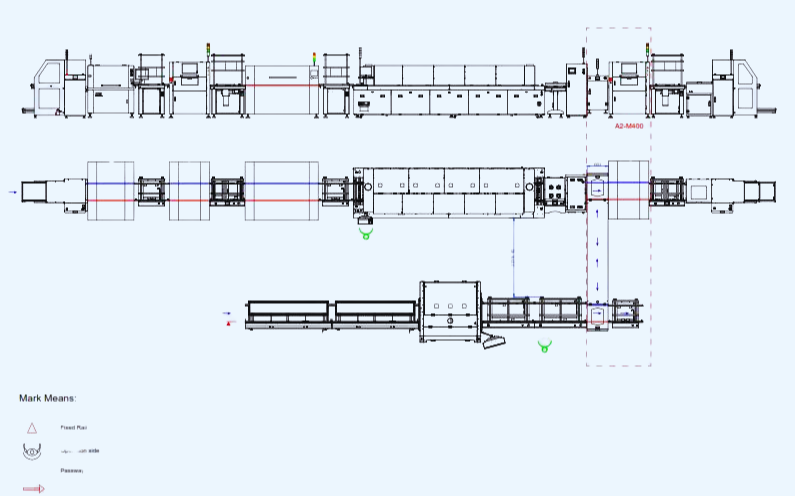

State-of-the-Art SMT Automation Solutions

Automated Inventory Management Made Easy

Maximum Precision and Efficiency in SMD Component Counting

Boost performance and reliability with cutting-edge technology

- Counting speeds within 6-10 seconds per reel.

- Always have up-to-date component inventory available.

- Direct integration into your ERP system.

- Cost reduction leading to ROI in no time.

- Usable in goods receipt, storage, or directly in production.

- Advanced technology with intelligent algorithms.

- Robust design.

- Low maintenance.

- Quick learning curve for employees.

Why Electronics Manufacturers Worldwide Choose allSMT

Over 20 Years of Experience

For more than two decades, we have been leaders in the electronics industry, offering proven technologies that can be precisely tailored to your specific production processes.

High Effectiveness

As a global provider of total-line solutions for the electronics industry, allSMT offers everything from prototype development to fully automated electronics production.

Short Delivery Times

By automating internal processes and utilizing cutting-edge technologies, we minimize delivery times and maximize the efficiency of our production.

Top Value for Money

According to our customers, the machines we deliver achieve an exceptionally long service life while requiring minimal maintenance.

Trendsetter in Technology

As pioneers in the industry, we set trends and develop technologies that are often imitated but never equaled.

Personalized Consulting & Support

With our support and personalized project management, we are always by your side. Our experts create tailor-made solutions for your specific requirements.

State-of-the-Art SMT Automation Solutions by allSMT Part.2

Reduce machine downtimes sustainably now

Reliably Connect SMD-Component Tapes

Precision splicing of 8, 12, 16, and 24 mm SMD tapes

- Unique SMD tape splicing system,

- Engineering Made by SASinno-VennTek

- Automatic tape width adjustment for 8, 12, 16, 24 mm

- Empty tape detection via camera system

- Supports SMD paper and plastic tapes (Blister)

- Rewinding function

- Electric roller aid for ergonomic transport

- PC with touchscreen

- Fast learning curve for employees

This Is How We Collaborate With You:

Before we create a non-binding offer, we analyze your requirements and discuss your specific needs together. Our experts then develop tailor-made solutions to optimize your processes and increase your efficiency.

5 Steps to the Perfect Solution